With over 32 years of experience

Covering an area of 20000 square meters

Annual production exceeds 70 units

There are currently over 120 employees

Harbin Mingyang Industrial Furnace, established in 1992, is a leading manufacturer specializing in industrial furnace equipment. Our core products include carbottom furnaces(bogie hearth furnace), pit furnaces, box furnaces, chain furnaces, and mesh belt furnaces, among a variety of other industrial heat treatment equipment. We also offer customized heat treatment production lines tailored to meet specific customer requirements. With a facility covering 220,000 square feet, including 110,000 square feet of production space, Mingyang Furnace achieves an annual output of over 70 units. Our team consists of more than 120 employees, including 25 skilled engineers and technical experts.

Dedicated to serving industries such as aerospace, aviation, nuclear power, chemical machinery, forging, and ceramics, we provide efficient, energysaving heat treatment solutions. Since 2006, Mingyang has achieved substantial technical advancements, including the development of China’s largest dualpurpose carburizing and nitriding furnace, as well as various other innovative industrial furnace products. Our company holds 30 patented technologies and has maintained ISO9000, ISO14000, and ISO18000 certifications for ten consecutive years.

Committed to innovation, Mingyang collaborates extensively with top research institutions and industry leaders both domestically and abroad. Our products are exported to the United States, Canada, Japan, South Korea, Saudi Arabia, South Africa, and numerous other regions. Mingyang Furnace is dedicated to driving technological progress in the industry through innovations that prioritize energy efficiency and environmental sustainability. With groundbreaking products like the "Movable RearWall VariableVolume CarBottom Heat Treatment Furnace" and the "90° Rotating Seal Mechanism," we have made notable advances in enhancing energy efficiency, reducing emissions, and optimizing equipment performance.

Mingyang Furnace remains focused on delivering highquality products and exceptional service, striving to exceed customer expectations and lead the way in industrial heat treatment solutions.

Mingyang

industrial furnace

Corporate

Culture

Idea

Mingyang Industrial Furnace always adheres to the customer-centric philosophy of technological innovation, energy conservation and environmental protection.

Culture

The company attaches great importance to the professional growth and teamwork of its employees, and is committed to creating a positive and progressive corporate culture, meeting customer needs with high-quality products and services, and promoting technological progress in the industry.

Development

History

2022

Development

History

2021

Development

History

2019

Development

History

2017

Development

History

2016

Development

History

2016

Development

History

2013

Development

History

2011

Development

History

2010

Development

History

2008

Development

History

2006

Development

History

2003

Development

History

1996

Development

History

1992

mingyang industrial furnace

Star

Product

Test content

Test Content

Test Content

Test Content

Mingyang

industrial furnace

Qualification

Certification

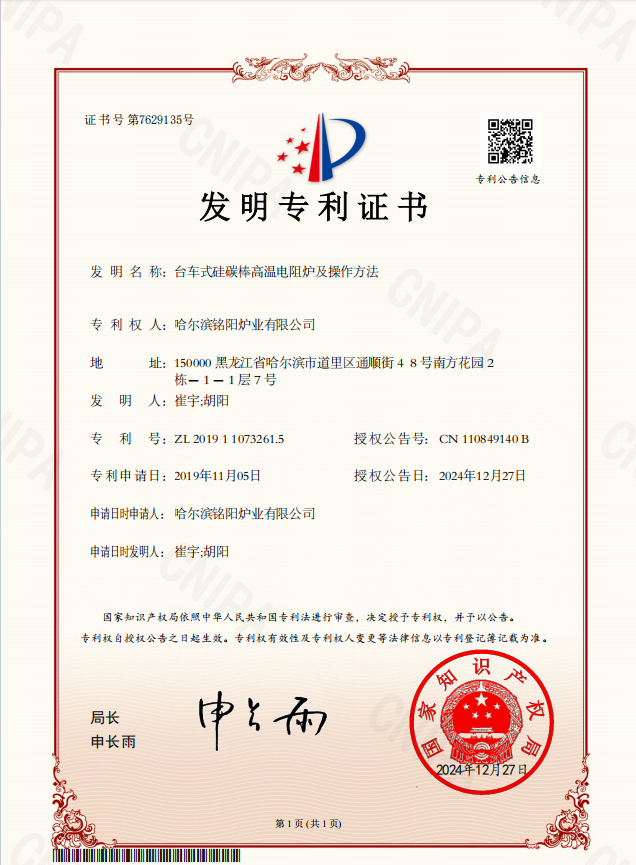

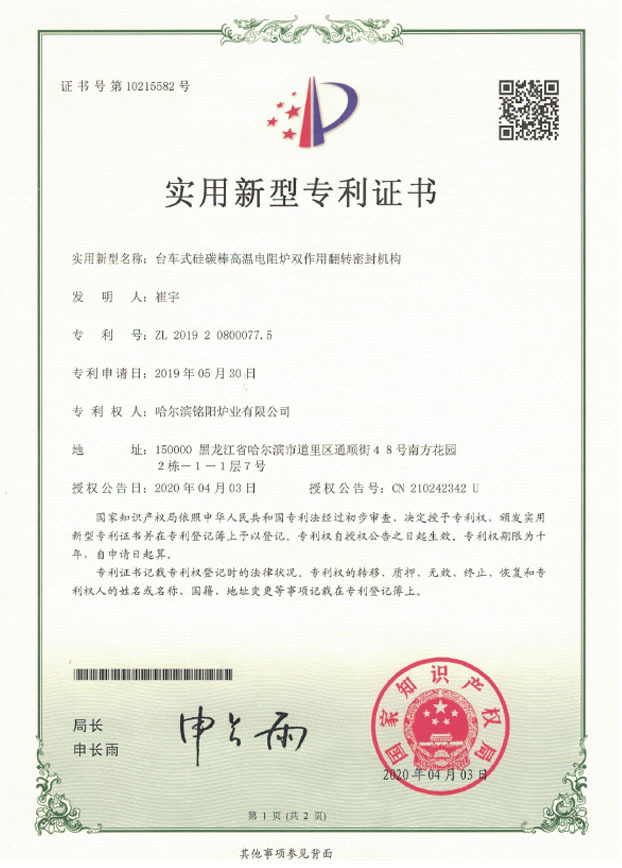

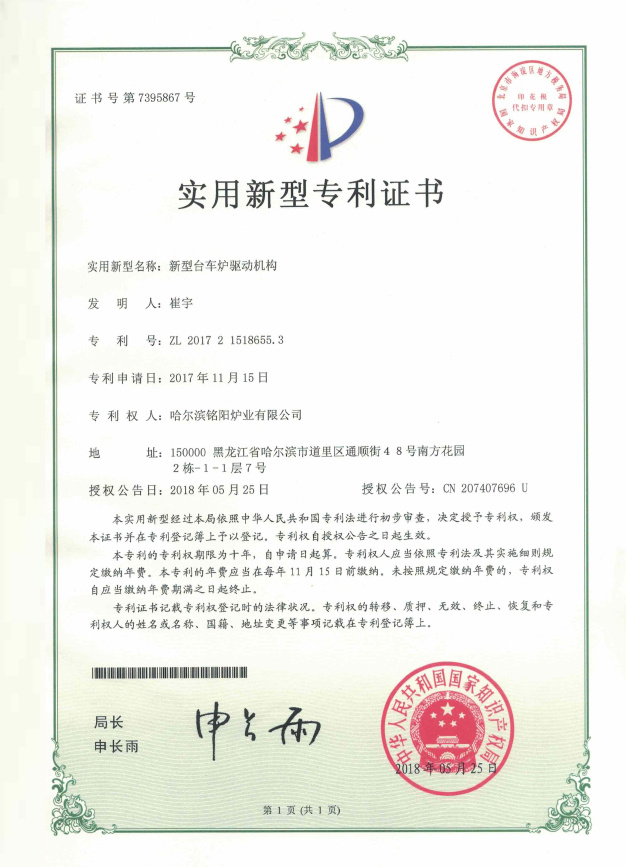

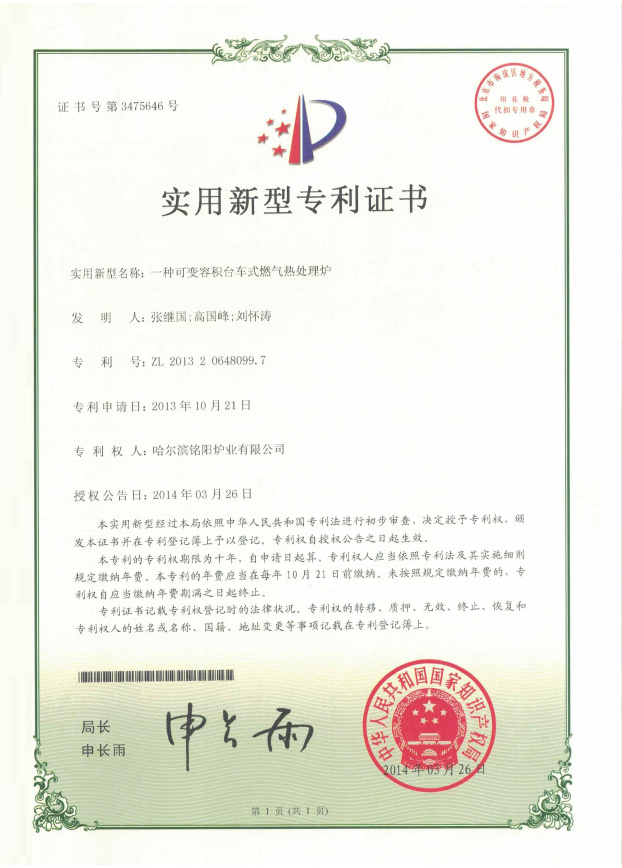

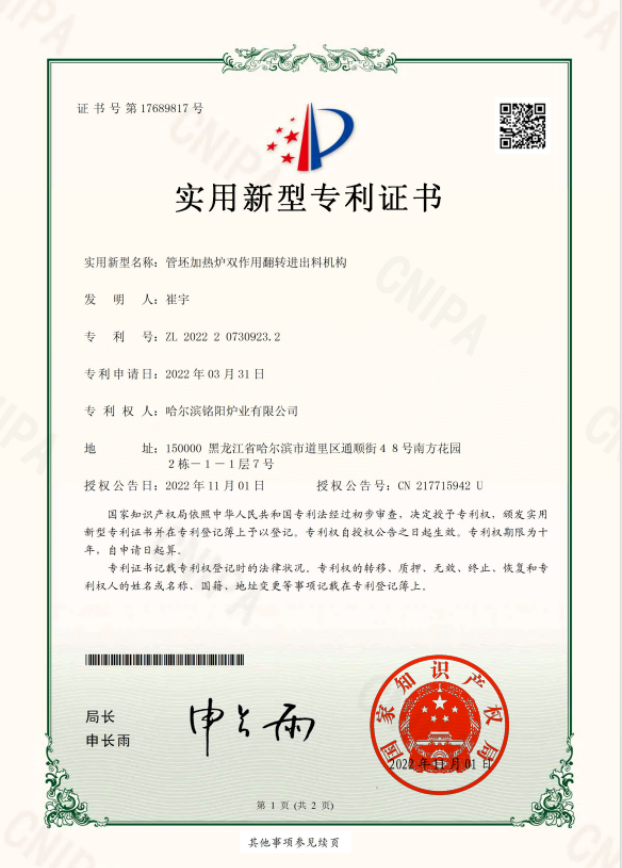

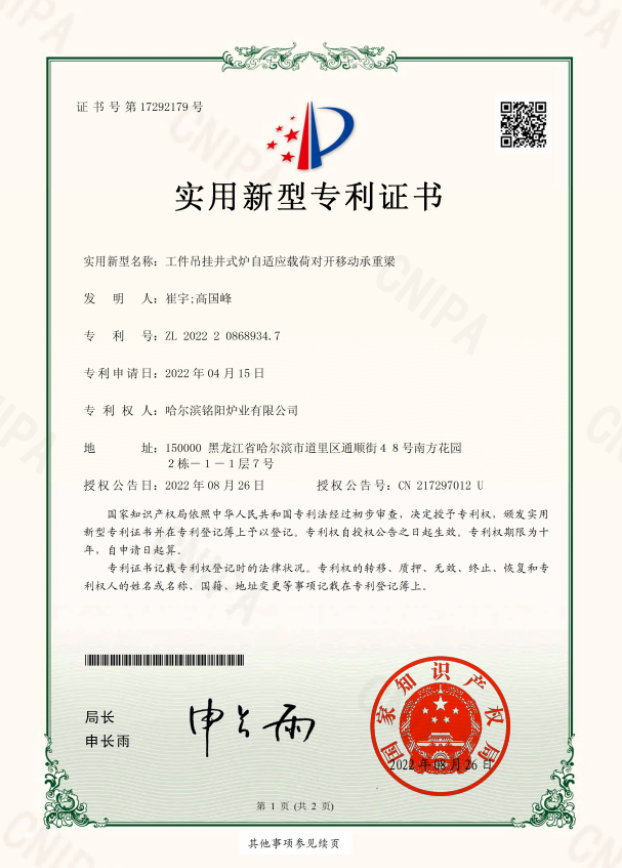

The company successfully registered a trademark in 2008, owns 30 patented technologies, and has passed ISO9000, ISO14000, and ISO18000 management system certifications for 10 consecutive years. Mingyang Furnace Industry has established technological exchanges and cooperation with companies from countries such as the United States, Canada, Japan, South Korea, Saudi Arabia, and South Africa, making its products competitive and influential in the international market.

Bogie type silicon carbon rod high temperature resistance furnace and operation method

Dual-Action Flip-Seal Mechanism for Car-Bottom High-Temperature Furnace with Silicon Carbide Heating Elements

Novel Drive Mechanism for Bogie Hearth Furnace

Variable-Volume Natural Gas Bogie Hearth Furnace

Dual-Action Flip Loading and Unloading System for Tube Heating Furnace

Adaptive Load-Bearing Double-Swing Beam for Suspended Workpieces in Pit Furnace

If you are interested in our products, please leave your email and we will contact you as soon as possible.

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

These cookies are necessary for basic functions such as payment. Standard cookies cannot be turned off and do not store any of your information.

These cookies collect information, such as how many people are using our site or which pages are popular, to help us improve the customer experience. Turning these cookies off will mean we can't collect information to improve your experience.

These cookies enable the website to provide enhanced functionality and personalization. They may be set by us or by third-party providers whose services we have added to our pages. If you do not allow these cookies, some or all of these services may not function properly.

These cookies help us understand what you are interested in so that we can show you relevant advertising on other websites. Turning these cookies off will mean we are unable to show you any personalized advertising.