Process Treatment

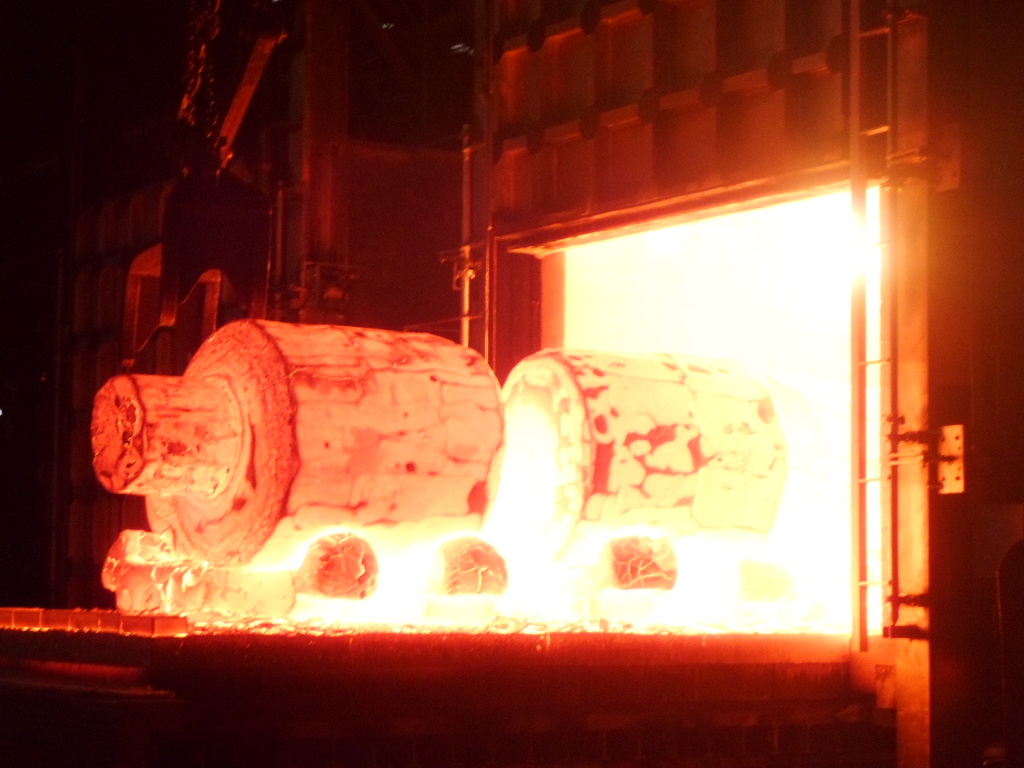

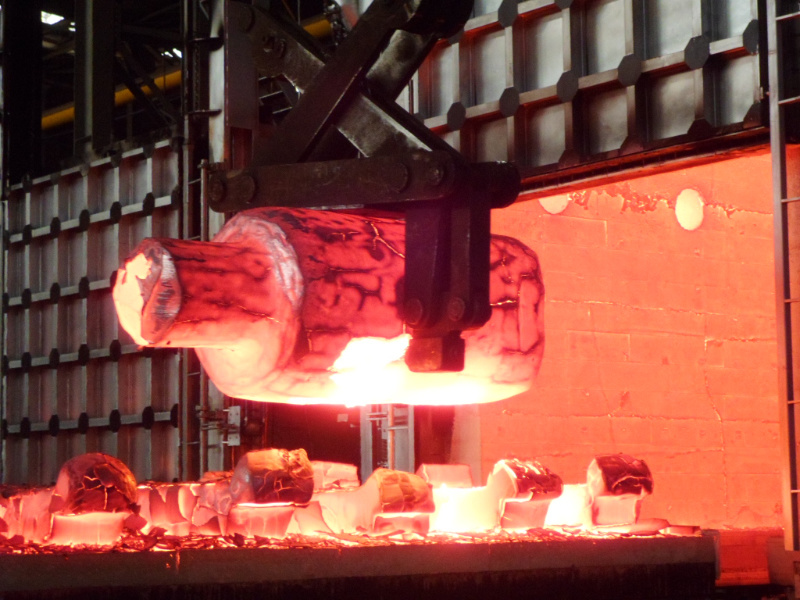

Heat treatment is a vital process in material engineering, designed to alter the physical and mechanical properties of materials, particularly metals and alloys, to enhance their performance. This process involves controlled heating and cooling to achieve desired properties such as improved hardness, strength, toughness, and resistance to wear and deformation.

mingyang industrial furnace

Application

Products

Forging Furnace for Marine Connecting Rod

Forging Furnace for Marine Crankshafts

Forging Furnace for Metallurgical Industry

With over 32 years of experience

Covering an area of 20000 square meters

Annual production exceeds 70 units

There are currently over 120 employees

Harbin Mingyang Furnace Industry was established in 1992 and is a professional enterprise that produces industrial furnace equipment. Its main products include trolley furnaces, well furnaces, box furnaces, cast chain furnaces, mesh belt furnaces, and other industrial heat treatment equipment. It can also design and manufacture various non-standard heat treatment production lines according to different customer needs. The company covers an area of 20000 square meters, with a building area of 10000 square meters, an annual output of over 70 units, and more than 120 employees, including 25 engineers and technicians.

The company focuses on multiple fields such as aviation, aerospace, nuclear industry, chemical machinery, forging, ceramics, etc., providing efficient and energy-saving heat treatment solutions. Since 2006, Mingyang Furnace Industry has made significant breakthroughs in multiple technological fields, including the development and manufacturing of China's largest carburizing/nitriding dual-purpose furnace, as well as other innovative industrial furnace products. The company has 30 patented technologies and has passed ISO9000, ISO14000, and ISO18000 management system certifications for 10 consecutive years.

Mingyang Furnace Industry actively cooperates with domestic and foreign research institutions and industry leaders, exporting its products to multiple countries and regions such as the United States, Japan, South Korea, Saudi Arabia, and South Africa. The company is committed to technological innovation, pursuing energy conservation and environmental protection, reducing pollution emissions, and continuously promoting technological progress in the industry. By developing innovative products such as the "Rear Wall Mobile Variable Capacity Trolley Heat Treatment Furnace" and the "90 ° Flip Side Sealing Mechanism", the company has achieved significant results in energy conservation, environmental protection, and performance improvement of heat treatment equipment.

We always adhere to customer centricity, meet customer needs with high-quality products and services, provide innovative heat treatment technology solutions for the industry, and become a leader in the field of industrial heat treatment furnaces.

mingyang industrial furnace

Star

Product

Test content

Test Content

Test Content

Test Content

mingyang industrial furnace

Application

Industries

mingyang industrial furnace

Qualification

Certification

The company successfully registered a trademark in 2008, owns 30 patented technologies, and has passed ISO9000, ISO14000, and ISO18000 management system certifications for 10 consecutive years. Mingyang Furnace Industry has established technological exchanges and cooperation with companies from countries such as the United States, Japan, South Korea, Saudi Arabia, and South Africa, making its products competitive and influential in the international market.

mingyang industrial furnace

FAQ

Yes, our furnaces incorporate energy-saving designs, including high-efficiency insulation, intelligent power control, and optimized heating systems to reduce energy consumption and emissions.

Yes, our Car Bottom Furnaces, Large Pit Furnaces, and Quenching Furnace Groups are designed to accommodate heavy machinery parts, large welded components, aerospace alloys, and shipbuilding materials, with load capacities reaching up to 200T.

The lead time depends on the complexity and size of the equipment. Standard furnaces typically take 8–12 weeks, while large custom projects may take longer. Contact us for a detailed production timeline.

We specialize in manufacturing industrial heat treatment equipment, including Car Bottom Furnaces, Pit Furnaces, Box Furnaces, Continuous Furnaces, and Quenching Furnace Groups. We also provide customized solutions for specific industrial needs, including forging, annealing, normalizing, quenching, and tempering.

Our furnaces are widely used in heavy industry, shipbuilding, aerospace, automotive parts, chemical processing, energy, petroleum, non-ferrous metals, and precision manufacturing. We offer customized solutions to meet the specific requirements of each sector.

Yes, we offer fully customized furnace solutions. We can adjust furnace dimensions, maximum temperature, heating power, temperature control methods, and load capacity to meet your production needs.

Car Bottom Furnaces (Bogie Hearth Furnaces) are ideal for processing large, heavy components due to their high load capacity, ease of loading and unloading, and excellent temperature uniformity. They are widely used for stress relief, annealing, and normalizing in industries such as aerospace, shipbuilding, and heavy machinery manufacturing.

Continuous Furnaces are designed for high-volume, automated production, providing consistent and efficient processing.

Batch Furnaces are ideal for custom or varied production runs, offering flexibility in treating different materials and heat treatment cycles.

Yes, we provide specialized heat treatment production lines for aluminum alloys, titanium alloys, and non-ferrous metals, including quenching, aging, and annealing furnaces tailored for these materials.

We integrate advanced control systems, including Intelligent Instrumentation, PLC Control, Computer Distributed Control, and Manual Control with Digital Displays, ensuring precise temperature regulation and uniform heating performance.

Online Message

If you are interested in our products, please leave your email and we will contact you as soon as possible. Thank you!