Exploring the Latest Advancements in Industrial Heat Treatment Furnaces

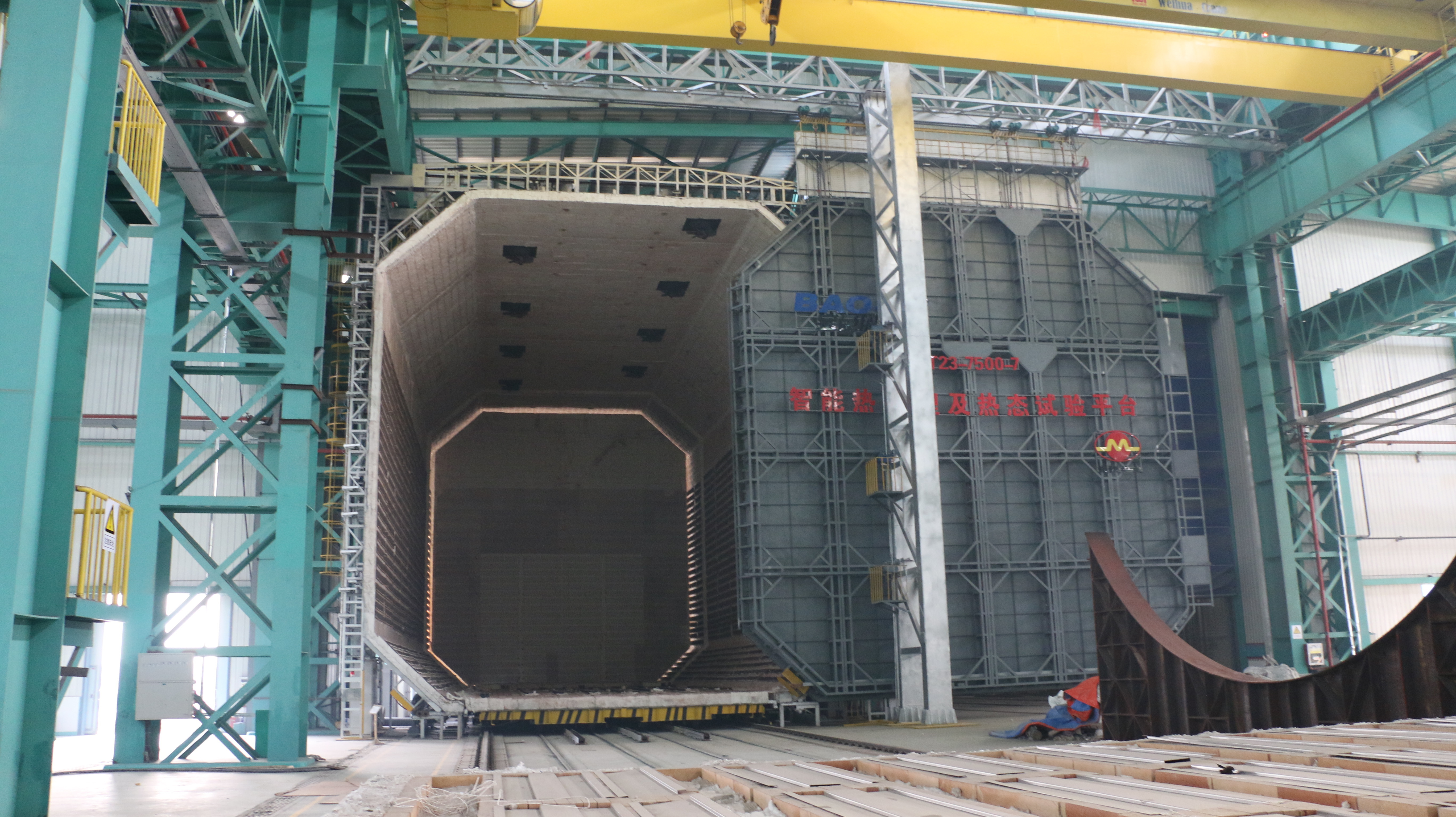

One of the most notable advancements in these furnaces is the integration of smart technology. Modern industrial heat treatment furnaces now feature advanced control systems that allow for real-time monitoring and adjustment of temperature and atmosphere conditions. This level of automation not only improves precision in the heat treatment process but also reduces the chances of human error. Operators can access data remotely, enabling more effective management of production processes and enhancing overall efficiency.

Additionally, the newest models are designed with energy efficiency in mind. They often utilize advanced insulation materials and energy recovery systems, which significantly reduce energy consumption compared to older models. This not only lowers operational costs but also aligns with global sustainability goals, as industries are increasingly pressured to minimize their carbon footprint. The ability to reduce energy usage while maintaining high performance is a crucial consideration for companies looking to invest in modern industrial heat treatment furnaces.

Another innovative feature found in the latest heat treatment furnaces is their versatile processing capabilities. These furnaces can accommodate a variety of heat treatment methods, including annealing, hardening, tempering, and more, all within a single unit. This flexibility allows manufacturers to optimize their processes and adapt to changing production needs without requiring multiple, separate machines.

In terms of material handling, newer industrial heat treatment furnaces are equipped with improved loading and unloading systems that streamline the workflow. Automated systems can handle heavier loads and ensure consistent placement within the furnace, thereby enhancing the uniformity of the heat treatment process. This innovation results in higher quality outputs and reduced cycle times, which are critical for meeting tight production schedules.

Lastly, safety enhancements are a top priority in the design of the newest industrial heat treatment furnaces. With advanced monitoring systems and safety interlocks, these furnaces ensure that operators are protected from potential hazards associated with high-temperature processes. This focus on safety not only protects employees but also helps companies comply with stringent industry regulations.

In conclusion, the newest industrial heat treatment furnaces are at the forefront of technological advancements, offering improved efficiency, versatility, and safety. As industries continue to evolve, investing in these innovative systems will be vital for maintaining competitiveness and meeting the demands of modern manufacturing.

If you are interested in our products, please leave your email and we will contact you as soon as possible.

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

These cookies are necessary for basic functions such as payment. Standard cookies cannot be turned off and do not store any of your information.

These cookies collect information, such as how many people are using our site or which pages are popular, to help us improve the customer experience. Turning these cookies off will mean we can't collect information to improve your experience.

These cookies enable the website to provide enhanced functionality and personalization. They may be set by us or by third-party providers whose services we have added to our pages. If you do not allow these cookies, some or all of these services may not function properly.

These cookies help us understand what you are interested in so that we can show you relevant advertising on other websites. Turning these cookies off will mean we are unable to show you any personalized advertising.