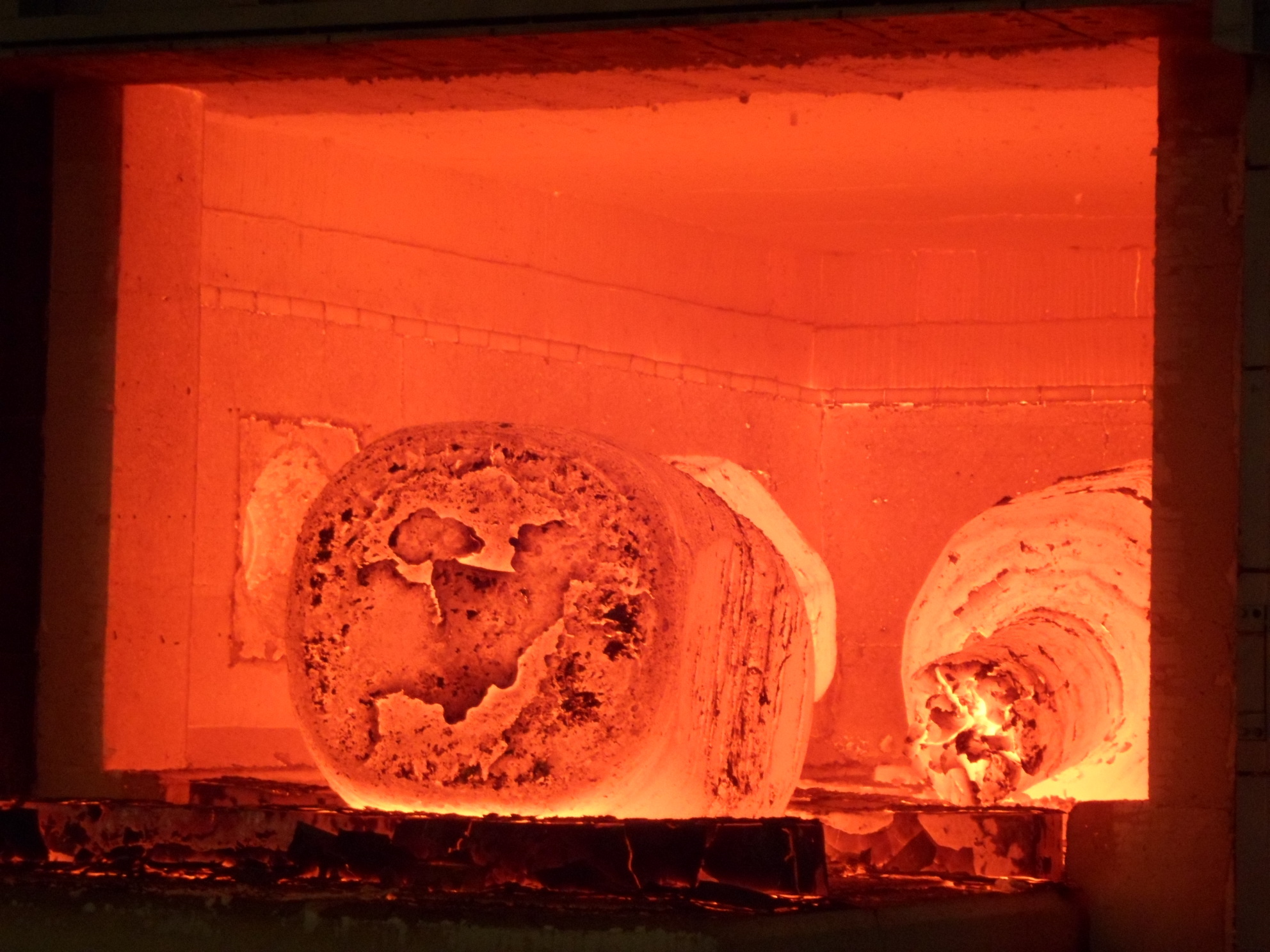

Unlocking Efficiency: The Advantages of Advanced Large Component Furnaces in Industrial Applications

One of the primary benefits of advanced large component furnaces is their ability to provide uniform temperature distribution. This feature is crucial for processes such as annealing and quenching, where even heat treatment is necessary to achieve the desired mechanical properties of materials. Traditional furnaces often suffer from hot and cold spots, which can lead to inconsistent results; however, advanced designs incorporate sophisticated temperature control systems that ensure every part of the component is treated evenly.

Moreover, these furnaces often feature advanced monitoring and automation capabilities. With the integration of smart technology, operators can precisely control the heating and cooling cycles, monitor energy consumption, and gather data analytics that can improve operational efficiency. This level of automation not only minimizes human error but also enhances safety within the production environment.

Another significant aspect of advanced large component furnaces is their energy efficiency. Modern designs emphasize sustainability by incorporating materials and technologies that reduce energy consumption during operation. By utilizing advanced insulation and efficient heating methods, these furnaces help manufacturers lower their operating costs and reduce their carbon footprint, aligning with contemporary environmental standards.

The versatility of advanced large component furnaces also cannot be overlooked. They can accommodate a variety of materials, including metals, ceramics, and composites, making them suitable for a wide range of applications. This adaptability allows manufacturers to expand their capabilities and offer a broader array of products without needing multiple types of furnaces.

Furthermore, the design of these furnaces often includes features that facilitate easy loading and unloading of components, which streamlines the production process. This is particularly beneficial in high-volume operations where time is of the essence. The ease of use contributes to reduced labor costs and improved turnaround times, enabling companies to better meet customer demands.

In conclusion, advanced large component furnaces represent a significant advancement in industrial equipment technology. Their ability to deliver uniform heating, integrate smart technology, enhance energy efficiency, and provide versatility makes them indispensable in modern manufacturing processes. Industries that invest in these furnaces will likely see improved product quality, reduced operational costs, and increased competitive advantage in the marketplace. As the industrial sector continues to evolve, the role of such advanced equipment will only become more critical to success.

If you are interested in our products, please leave your email and we will contact you as soon as possible.

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

These cookies are necessary for basic functions such as payment. Standard cookies cannot be turned off and do not store any of your information.

These cookies collect information, such as how many people are using our site or which pages are popular, to help us improve the customer experience. Turning these cookies off will mean we can't collect information to improve your experience.

These cookies enable the website to provide enhanced functionality and personalization. They may be set by us or by third-party providers whose services we have added to our pages. If you do not allow these cookies, some or all of these services may not function properly.

These cookies help us understand what you are interested in so that we can show you relevant advertising on other websites. Turning these cookies off will mean we are unable to show you any personalized advertising.