Understanding the Importance of New Alloy Tempering Furnaces in Heat Treatment Processes

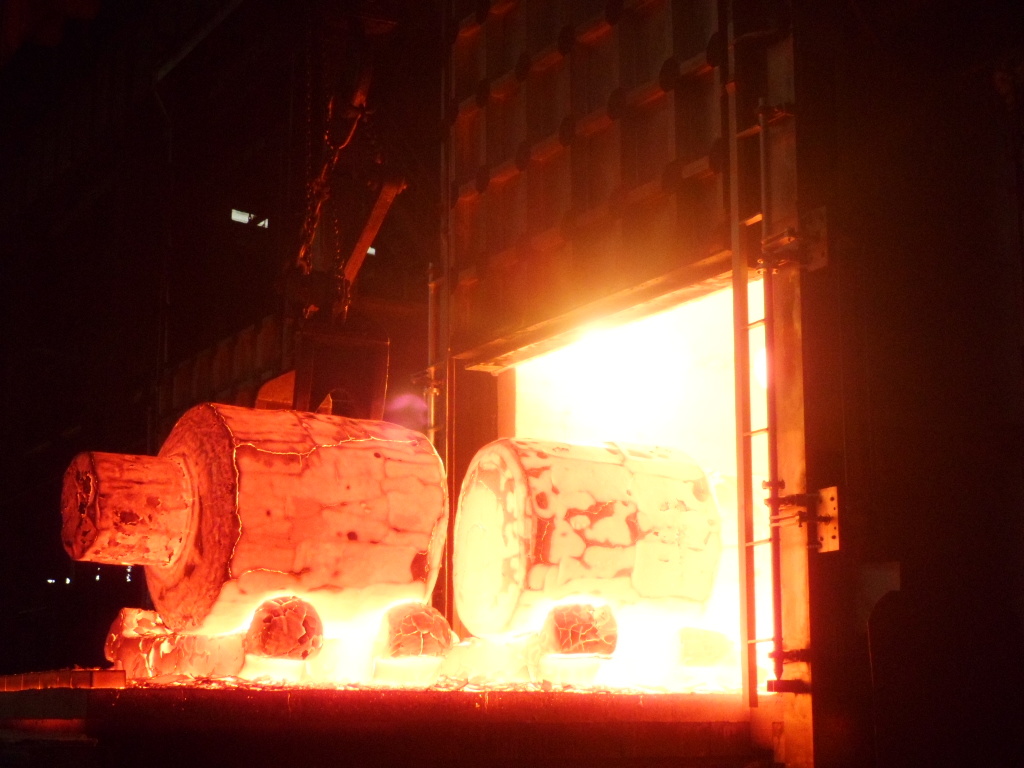

New alloy tempering furnaces utilize advanced technologies that provide superior thermal management and energy efficiency. This innovation allows manufacturers to optimize their production processes, resulting in high-quality end products. The furnace’s ability to reach and maintain specific temperatures is essential to alter the microstructure of the alloys, which directly influences their hardness, toughness, and ductility.

One of the key features of modern tempering furnaces is their ability to accommodate various alloy compositions. As industries evolve and demand new materials with specific properties, the flexibility of these furnaces to handle different alloys becomes increasingly important. This versatility not only enhances production capabilities but also supports the development of innovative materials for applications across various sectors, from automotive to aerospace.

Another significant advantage of new alloy tempering furnaces is their user-friendly interfaces and automation capabilities. Many of these furnaces come equipped with advanced monitoring systems that allow operators to track temperature profiles and make adjustments in real-time. This precision reduces the likelihood of errors during the tempering process, leading to consistent and repeatable results, which are essential for quality assurance in manufacturing.

Moreover, the efficiency of new alloy tempering furnaces plays a crucial role in reducing operational costs. By optimizing energy consumption and minimizing waste, manufacturers can achieve better profitability while also meeting environmental sustainability goals. As industries are under increasing pressure to lower their carbon footprints, the adoption of energy-efficient equipment like tempering furnaces is a step in the right direction.

In summary, new alloy tempering furnaces represent a significant advancement in heat treatment technology. Their ability to provide precise temperature control, accommodate various alloys, and enhance production efficiency positions them as essential tools for modern manufacturing. As the industry continues to evolve, investing in such innovative equipment will be fundamental for businesses looking to stay competitive and meet the demands of future markets. These furnaces not only contribute to the production of high-quality materials but also play a pivotal role in the sustainability of industrial practices.

If you are interested in our products, please leave your email and we will contact you as soon as possible.

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

These cookies are necessary for basic functions such as payment. Standard cookies cannot be turned off and do not store any of your information.

These cookies collect information, such as how many people are using our site or which pages are popular, to help us improve the customer experience. Turning these cookies off will mean we can't collect information to improve your experience.

These cookies enable the website to provide enhanced functionality and personalization. They may be set by us or by third-party providers whose services we have added to our pages. If you do not allow these cookies, some or all of these services may not function properly.

These cookies help us understand what you are interested in so that we can show you relevant advertising on other websites. Turning these cookies off will mean we are unable to show you any personalized advertising.