Understanding the Benefits and Functions of Durable Tempering Furnaces in Industrial Applications

One of the primary benefits of using a durable tempering furnace is its ability to provide consistent and reliable heating. This consistency is essential for achieving uniform hardness and strength in metals, which are critical for applications in various industries, including automotive, aerospace, and manufacturing. A well-designed furnace will maintain a stable temperature throughout the heating process, ensuring that the materials are uniformly treated.

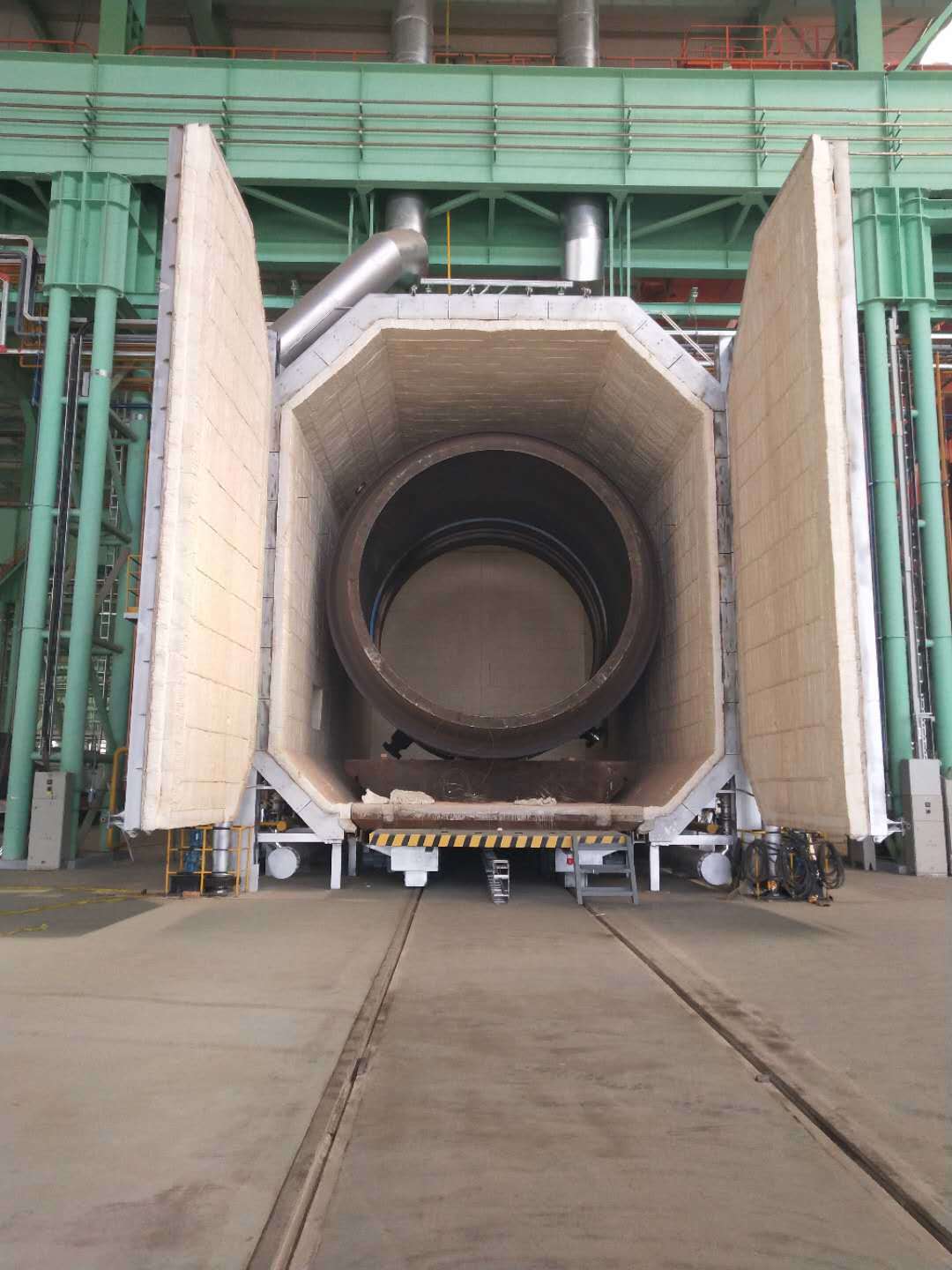

Moreover, durability is a key feature of these furnaces. Industrial environments can be harsh, with high temperatures and significant wear and tear. A durable tempering furnace is constructed from high-quality materials that can withstand these conditions, thus ensuring a longer lifespan and reduced maintenance costs. Investing in a robust furnace means fewer disruptions in production and greater efficiency in the long run.

Another important factor to consider is the energy efficiency of a tempering furnace. Modern designs prioritize energy conservation, which not only lowers operational costs but also aligns with sustainability goals in manufacturing. Utilizing advanced insulation materials and energy-efficient heating elements, a durable tempering furnace can significantly reduce energy consumption while maintaining optimal performance.

In addition to these benefits, it's essential to evaluate the furnace's capacity and features based on specific operational needs. Factors such as the size of the components being treated, the desired temperature range, and the production volume will influence the choice of furnace. Some furnaces may also offer advanced control systems that allow for precise temperature regulation and monitoring, adding to their effectiveness and reliability.

Lastly, understanding the various types of tempering furnaces available in the market can help businesses make informed decisions. Options range from batch furnaces to continuous furnaces, each designed to cater to specific production requirements. By selecting the appropriate type of durable tempering furnace, companies can optimize their heat treatment processes, ensuring that their products meet the highest quality standards.

In conclusion, durable tempering furnaces are indispensable tools in the industrial sector, offering numerous advantages in terms of performance, durability, and energy efficiency. Businesses that prioritize the selection of high-quality tempering furnaces will benefit from improved product quality and operational efficiency, ultimately leading to enhanced competitiveness in the market.

If you are interested in our products, please leave your email and we will contact you as soon as possible.

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

These cookies are necessary for basic functions such as payment. Standard cookies cannot be turned off and do not store any of your information.

These cookies collect information, such as how many people are using our site or which pages are popular, to help us improve the customer experience. Turning these cookies off will mean we can't collect information to improve your experience.

These cookies enable the website to provide enhanced functionality and personalization. They may be set by us or by third-party providers whose services we have added to our pages. If you do not allow these cookies, some or all of these services may not function properly.

These cookies help us understand what you are interested in so that we can show you relevant advertising on other websites. Turning these cookies off will mean we are unable to show you any personalized advertising.