Understanding Quality Alloy Tempering Furnaces: A Key Component in Industrial Heat Treatment

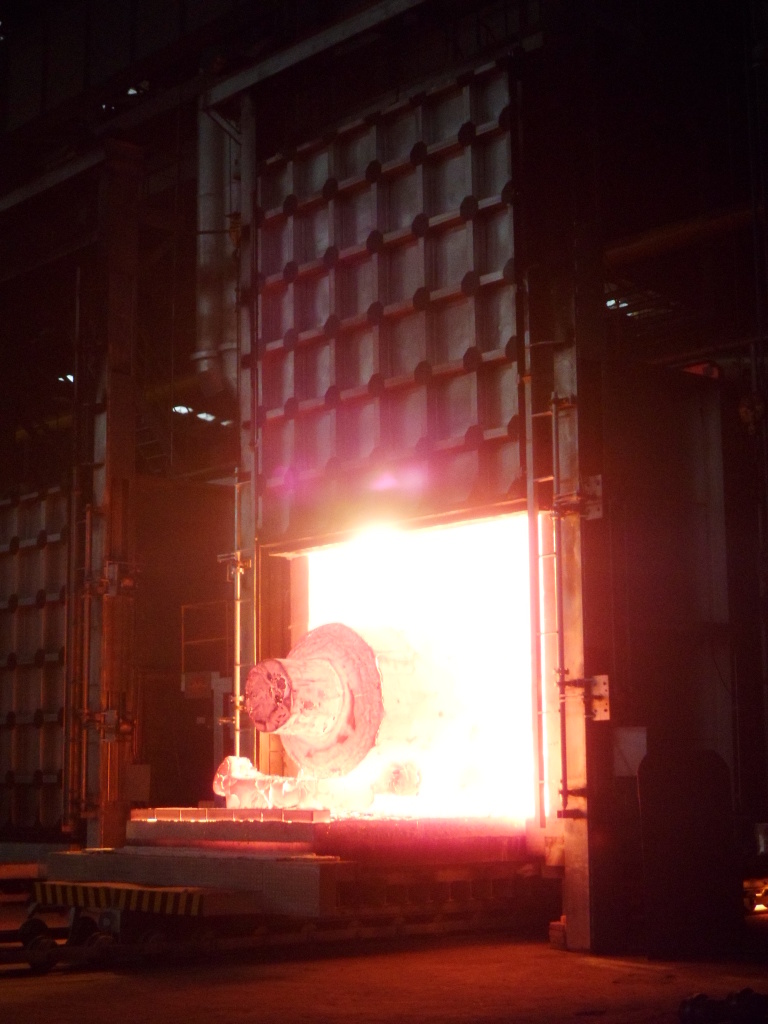

In the realm of industrial equipment and components, particularly within the foundry and heat treatment sectors, quality alloy tempering furnaces play an indispensable role. These furnaces are designed to temper metals, enhancing their mechanical properties, such as toughness and ductility, which are critical in various applications.

Tempering is a heat treatment process that involves heating a material to a temperature below its critical point, followed by cooling, typically in air. This procedure is paramount for achieving desired mechanical characteristics in alloyed steel and other metals. A quality alloy tempering furnace ensures that this process is carried out with precision, allowing for uniform heating and consistent results across batches.

One of the primary benefits of utilizing a quality alloy tempering furnace is the improvement of strength and hardness in metals. By carefully controlling the temperature and duration of the heating process, manufacturers can effectively reduce brittleness and enhance the overall durability of the material. This is particularly important in industries such as automotive, aerospace, and construction, where material failures can have catastrophic consequences.

Another significant aspect of quality alloy tempering furnaces is their energy efficiency. Modern furnaces are designed with advanced insulation and heating technologies that reduce energy consumption while maintaining optimal heating conditions. This not only lowers operational costs but also aligns with global efforts towards more sustainable manufacturing practices.

Moreover, the versatility of these furnaces cannot be overlooked. They can accommodate a wide range of alloys, including carbon steels, tool steels, and stainless steels. This adaptability makes them an essential investment for businesses looking to diversify their production capabilities and meet varying customer demands.

Quality alloy tempering furnaces also feature advanced monitoring and control systems. These systems provide real-time data on temperature, time, and atmospheric conditions within the furnace, allowing operators to make necessary adjustments and ensure that the tempering process meets specific standards. This level of control is vital for industries that require strict adherence to quality specifications.

In conclusion, understanding the importance of quality alloy tempering furnaces is crucial for businesses involved in industrial heat treatment. These furnaces not only enhance the mechanical properties of metals but also improve energy efficiency and operational control. By investing in high-quality tempering furnaces, companies can ensure that their products meet the rigorous demands of modern industries, ultimately fostering innovation and competitiveness in the market.

If you are interested in our products, please leave your email and we will contact you as soon as possible.

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

These cookies are necessary for basic functions such as payment. Standard cookies cannot be turned off and do not store any of your information.

These cookies collect information, such as how many people are using our site or which pages are popular, to help us improve the customer experience. Turning these cookies off will mean we can't collect information to improve your experience.

These cookies enable the website to provide enhanced functionality and personalization. They may be set by us or by third-party providers whose services we have added to our pages. If you do not allow these cookies, some or all of these services may not function properly.

These cookies help us understand what you are interested in so that we can show you relevant advertising on other websites. Turning these cookies off will mean we are unable to show you any personalized advertising.