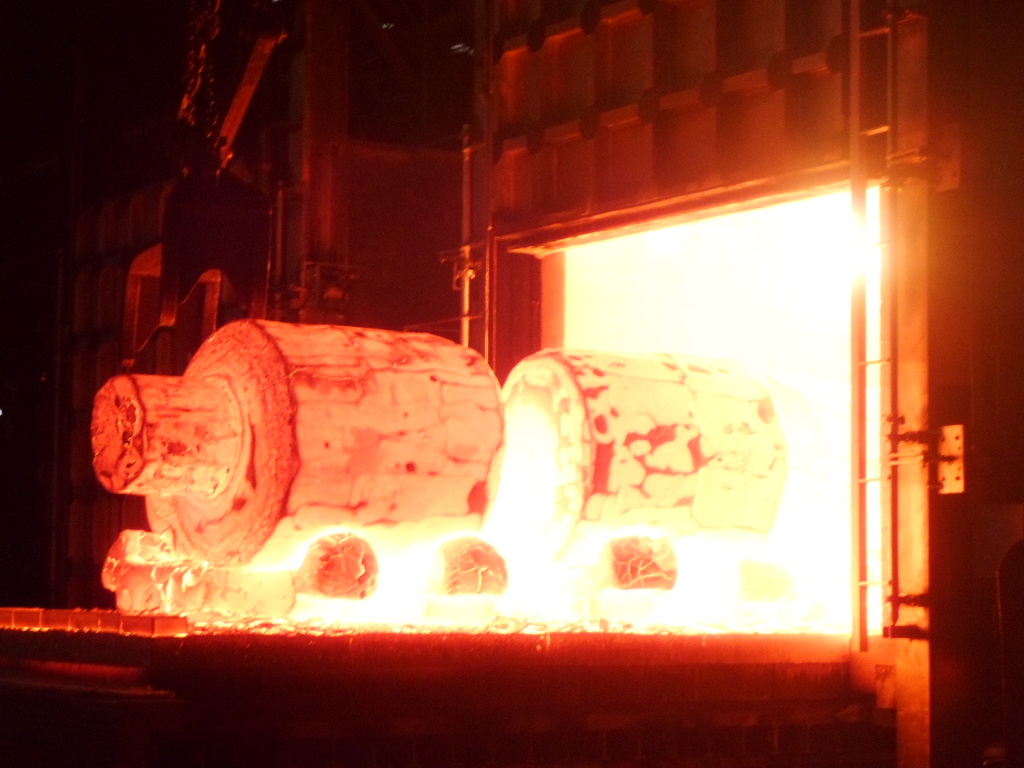

Stress Relief Furnace for Reactor Pressure Vessels

Category:

| Furnace Chamber Dimensions(L×W×H): | 27.08m × 8m × 8.3m |

| Maximum Operating Temperature: | 750°C |

| Temperature Uniformity: | ≤±10°C |

| Load Capacity: | 1200T |

| Temperature Control Method: | Manual |

| Application: | Stress Relief of pressure vessels, shell sections, and end caps |

The Stress Relief Furnace for Reactor Pressure Vessels is a robust Bogie Hearth Furnace (Car Bottom Furnace), specifically designed for the stress relief treatment of large-scale pressure vessels and their components. With its customizable design, this furnace is ideal for handling massive components such as reactor pressure vessels, shell sections, and end caps, ensuring optimal stress relief to enhance material strength and durability.

The furnace features a generous chamber size of 27.08m × 8m × 8.3m, providing ample space for large pressure vessel components. With a maximum load capacity of 1200 tons and a maximum operating temperature of 750°C, this furnace ensures the capacity to meet the demands of high-volume, heavy-duty applications.

Equipped with manual control, this furnace offers precision and flexibility for operators to ensure accurate temperature regulation during the stress relief process. The temperature uniformity of ≤±10°C ensures that the entire workpiece receives consistent treatment, critical for maintaining material integrity and performance.

This furnace is designed to be fully adaptable to various pressure vessel components, with customization options available to suit specific needs. The energy-efficient heating system ensures reliable performance, with a focus on delivering optimal stress relief treatment for your heavy-duty pressure vessel components.

Whether you're dealing with reactor pressure vessels, shell sections, or end caps, this furnace provides a powerful and efficient solution to ensure high-quality stress relief for your critical components in the nuclear and heavy industrial sectors.

previous item:

Online Message

If you are interested in our products, please leave your email and we will contact you as soon as possible. Thank you!

mingyang industrial furnace

Recommended

Products

Forging Furnace for Marine Connecting Rod