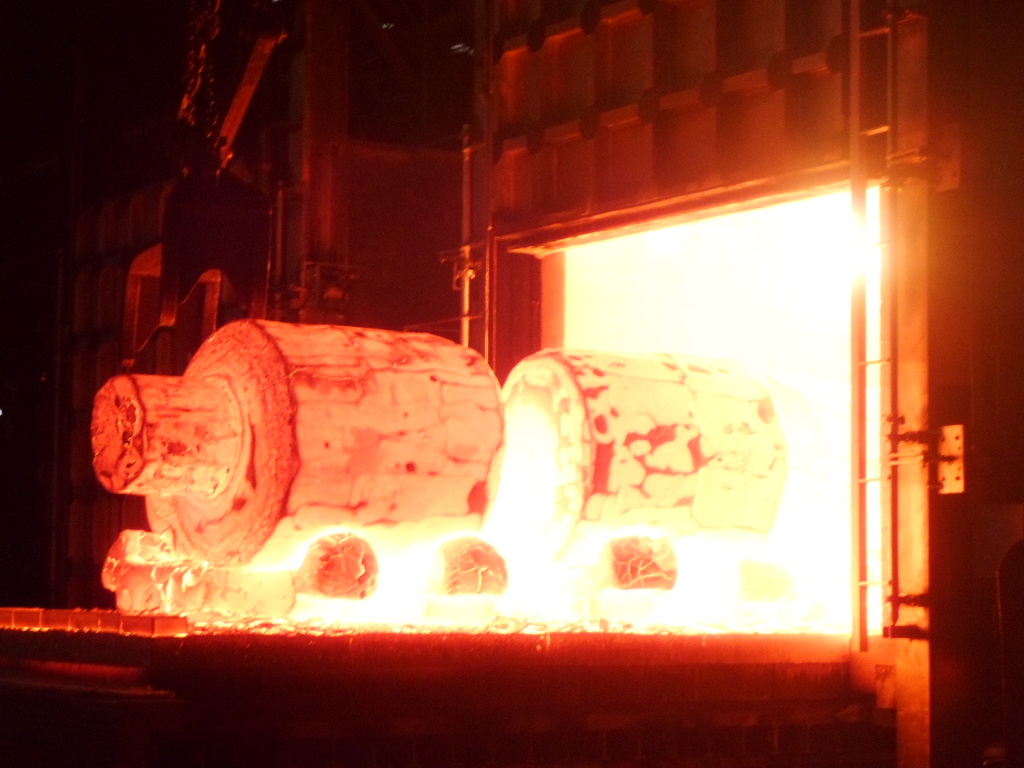

Forging Furnace for Marine Connecting Rod

Precision Forging Furnace is an intelligent heat treatment equipment specially designed for high-standard and high-efficiency heating needs in the field of metal forging. With the core advantages of rapid heating, precise temperature control, energy saving and consumption reduction, this product is widely used in the hot processing preheating links of automotive parts, high-strength fasteners, aviation forgings and various high-performance alloy materials.

Category:

Precision Forging Furnace is an intelligent heat treatment equipment specially designed for high-standard and high-efficiency heating needs in the field of metal forging. With the core advantages of rapid heating, precise temperature control, energy saving, and consumption reduction, this product is widely used in the hot processing preheating links of automotive parts, high-strength fasteners, aviation forgings, and various high-performance alloy materials.

The whole machine adopts an advanced electric heating or induction heating system, with a multi-zone temperature control module, to achieve uniform temperature distribution in the furnace, ensure that the billet reaches the set temperature in a short time, and effectively improve the plasticity and yield rate of forging materials. The control system has functions such as intelligent program setting, real-time temperature monitoring, and automatic recording of process parameters to meet the flexible call and fast switching of various forging processes.

MingYang Industrial Furnace uses high-strength insulation materials and high-temperature resistant alloy components in the furnace structure to ensure that the equipment is still stable and durable under a high-temperature continuous operation environment. For metal billets of different shapes and sizes, the product can be equipped with multi-section feeding tracks, automatic pushing systems, and infrared thermometers to achieve continuous and unmanned, efficient operation.

This series of heating furnaces incorporates the concept of energy saving in its design. Through heat recovery devices and optimized combustion control technology, it significantly reduces energy consumption and operating costs, is green and environmentally friendly, and meets the requirements of sustainable development of modern industry. At the same time, the equipment supports customized development services, and can be designed non-standardly according to the user's specific forging process and production capacity requirements, and flexibly adapt to various production lines.

Choosing Precision Forging Furnace not only improves the quality and production efficiency of forgings, but also provides reliable guarantees for enterprises to build an intelligent, efficient, and environmentally friendly forging production system.

| Effective Zone Dimensions (L×W×H): | 8.35m × 3.24m × 2.5m |

| Maximum Operating Temperature: | 1300°C |

| Temperature Uniformity: | ≤±15°C |

| Load Capacity: | 100T |

| Temperature Control Method: | PLC + Manual + Instrumentation |

| Application: | Forging heat treatment for marine diesel engine connecting rods |

Product Description:

The Forging Furnace for Marine Connecting Rod is a Bogie Hearth Furnace (also known as Car Bottom Furnace), specifically designed to meet the rigorous demands of marine diesel engine connecting rod heat treatment. This advanced furnace features a large effective zone of 8.35m × 3.24m × 2.5m, making it capable of handling large and heavy components with ease, ensuring efficient and consistent forging operations.

With a maximum operating temperature of 1300°C and temperature uniformity maintained within ±15°C, this furnace guarantees precision in heat treatment processes, delivering high-quality results for marine engine components. It has a remarkable load capacity of 100 tons, ideal for large-scale forging and heat treatment tasks.

The Bogie Hearth Furnace design enables the furnace to support heavy loads, offering excellent flexibility for various forging operations. The temperature is controlled using a combination of PLC, manual, and instrumentation, ensuring precise control over the heat treatment process.

We offer customized solutions for all your specific needs, whether it's adjustments in furnace dimensions, temperature control systems, or unique operational features. Our team works closely with you to design a forging furnace that matches your exact requirements, ensuring optimal performance for your marine component manufacturing.

This Car Bottom Furnace is perfect for companies in the marine industry, delivering durability, efficiency, and reliability for marine engine component forging.

previous item:

next item:

Online Message

If you are interested in our products, please leave your email and we will contact you as soon as possible. Thank you!

mingyang industrial furnace

Recommended

Products

Forging Furnace for Marine Connecting Rod