Forging Furnace for Marine Crankshafts

Category:

| Furnace Chamber Dimensions (L×W×H): | 9m × 4.5m × 2.8m |

| Maximum Operating Temperature: | 1100°C |

| Temperature Uniformity: | ±10°C |

| Maximum Loading Capacity: | 120T |

| Temperature Control Method: | PLC + Manual + Instrument |

| Application: | Forging heating for marine crankshafts |

Product Description:

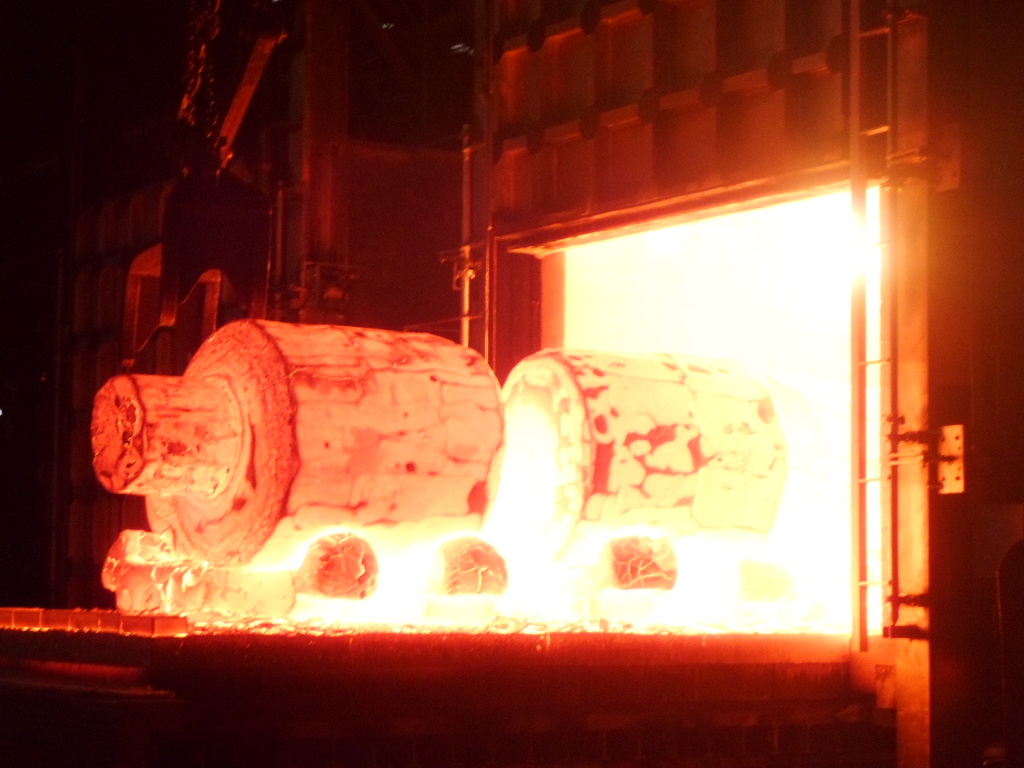

The Forging Furnace for Marine Crankshafts is a Bogie Hearth Furnace (Car Bottom Furnace) specifically designed for the precise and uniform heating of marine crankshafts before forging. This high-performance furnace is built to handle large and heavy crankshafts, ensuring superior temperature control and consistent heating quality, which is critical in marine engine manufacturing.

With a furnace chamber size of 9m × 4.5m × 2.8m, this system accommodates oversized crankshafts, making it ideal for large-scale marine component production. It operates at a maximum temperature of 1100°C, with exceptional temperature uniformity of ±10°C, ensuring precise and even heating throughout the entire workpiece. The robust construction supports a maximum loading capacity of 120 tons, allowing for the processing of heavy-duty marine crankshafts with ease.

Equipped with a PLC-based control system, complemented by manual and instrumentation control, this Car Bottom Furnace provides high-precision temperature management, ensuring optimal forging conditions. The Bogie Hearth design facilitates smooth material handling, allowing for easy loading and unloading of large components while minimizing downtime and improving operational efficiency.

Understanding that each marine engine manufacturing process is unique, we provide fully customizable solutions tailored to your production requirements. Whether you require adjustments in furnace dimensions, heating capacity, or control systems, our team will develop a bespoke solution to optimize your forging process.

This high-efficiency forging furnace is the ideal solution for marine engine manufacturers, ensuring durability, precision, and operational reliability. Contact us today to discuss customized options for your production needs and discover how our Bogie Hearth Furnace can enhance your manufacturing efficiency.

previous item:

next item:

Online Message

If you are interested in our products, please leave your email and we will contact you as soon as possible. Thank you!

mingyang industrial furnace

Recommended

Products

Forging Furnace for Marine Connecting Rod